Padua, June 2025 – The installation test of one of the two cryopumps for the MITICA experiment has been successfully completed. Designed by ITER and built by the French company SDMS in the framework of a F4E contract, the installation of these components marks an important step toward the completion of MITICA’s assembly — the injector designed to generate a beam of hydrogen ions at extremely high energy (up to 1 million electronvolts). All of this, with a very special ingredient.

There is a unique place in the Neutral Beam Test Facility – NBTF. It’s the place where extremely hot temperatures and extremely cold temperatures meet in the vacuum — together with coconuts.

It’s the same situation you find, coconuts aside, a few blocks away from our solar system, where the scorching heat of the Sun meets the extreme cold of the surrounding void.

But let’s take it step by step.

First, the vacuum.

To operate properly, MITICA must work in vacuum conditions similar to those of deep space. The beam line vessel (vacuum chamber) that hosts MITICA’s cryogenic pumps (or cryopumps) is designed for exactly this purpose: “to guarantee a sufficiently large volume, isolated from the external atmosphere, within which ultra-high vacuum conditions can be created,” as explained by Matteo Valente, Head of Thermo-mechanical Systems Engineering Group – Consorzio RFX.

Inside this volume, gases are injected — which is necessary for the experiment to function. At the same time, however, “ultra-high vacuum conditions must be maintained throughout the injector’s operation. The two cryopumps are precisely intended to pump out the gases in the vacuum chamber, maintaining the low pressures required for the whole system to work”, Valente says.

In this particular type of pump, gases are trapped within a matrix made of a very specific material.

And this is where our special ingredient comes into play.

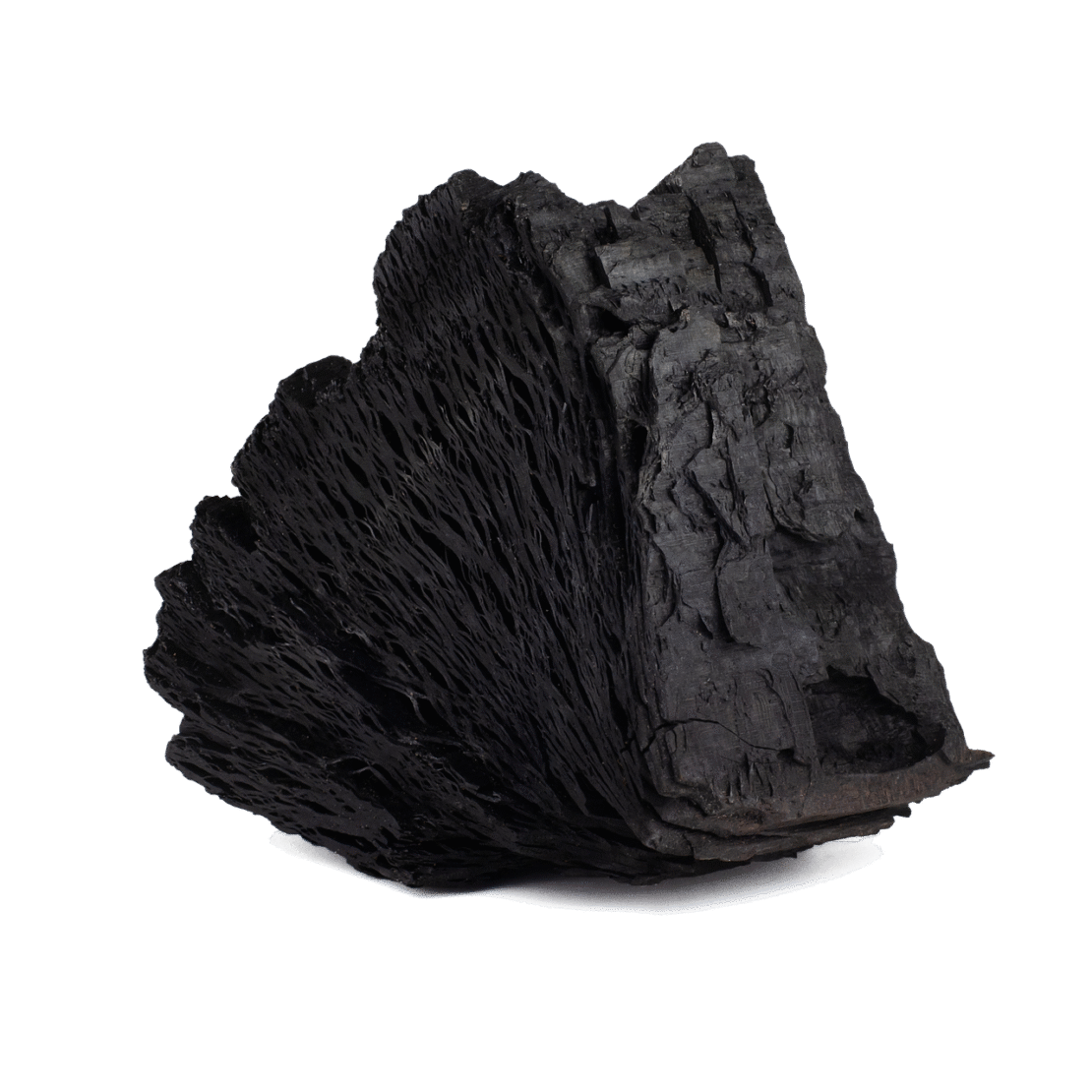

“Capturing these large amounts of gas is possible because the surfaces of the cryopumps are entirely coated with a special charcoal material, in the form of small pellets (1–2 mm). This material is derived from coconut shells. Its porosity and special internal structure allow it to absorb an extremely large quantity of gas particles — enough to maintain ultra-high vacuum conditions”, Valente continues.

The charcoal obtained from coconut is microporous —

its surface contains millions of tiny pores.

But for the absorption process to take place efficiently, the small pellets must be cooled to temperatures near absolute zero (–268°C).

At that point, the path is clear. Inside the vacuum chamber, the ion beam accelerated to 1 megavolt can travel freely and undisturbed, passing through the various internal components of the injector without interacting with any gas particles — all neatly trapped by our “coconuts”.

MITICA’s cryopumps are unparalleled in the world. At 8 meters long and 2.5 meters tall, they are the largest cryopumps ever built.

“One of MITICA’s objectives is, in fact, also to test this type of components and technologies”, Valente concludes.

The path of scientific research is paved with futuristic and highly advanced technologies, but it’s also thanks to the contribution of simple, yet ingenious ideas that it manages to take those extra steps forward — expanding the frontiers of knowledge and innovation.

For more details, visit the dedicated page on the ITER website and the one on Fusion for Energy website.

The MITICA cryopump system was designed and built in collaboration between ITER Organization, Consorzio RFX, and SDMS.

#fusion #technology #innovation