A plasma is a gas

composed of electrically charged particles

which are free to move about, known as

“the fourth state of matter“

Similar to what happens with the transition from the liquid state to the gaseous state, which is observed when the temperature is increased, the transition from gas to plasma is obtained when the temperature of a gas is brought to around 10,000 degrees. Under these conditions the gas atoms begin to split into ions and electrons, the gas then passes to the plasma state.

The main classification of the different types of plasmas present in nature sees two main families: cold plasmas and hot plasmas. More than temperature, what distinguishes the two types is the relative concentration of ions, electrons and atoms.

A plasma is called hot when the temperature of the ions is equal to or close to the temperature of the electrons. This normally happens when all the atoms are ionized and the plasma is practically composed only of ions and electrons. To reach this state, temperatures of at least 100,000 degrees are normally required, hence the name hot plasma.

Cold plasmas, on the other hand, have the property of having two very different temperatures for ions and electrons. The ions maintain the same temperature as the fraction of neutral gas atoms, the temperature of the environment in which the plasma is located (from a few tens to a few hundred degrees C). The electrons, on the other hand, are found at temperatures hundreds of times higher, typically around 10,000 degrees and above.

In cold plasmas, most of the heat is transmitted by the portion of neutral gas, while electrons, despite the high temperature, carry a small fraction of the overall heat. This means that both the electrons and the ions of the cold plasma can activate a chain of chemical reactions that would occur only at temperatures equivalent to those of the electrons, without practically changing the temperature of the materials to be treated.

This opens up a variety of applications related to surface treatment. They range from the realization of integrated circuits, the deposition of thin metal layers, the hardening of tools, to the pre-treatment of surfaces and fabrics to improve the adhesion of glues and dyes, the disinfection of containers and the treatment of biological tissues. Biological tissues such as plants, seeds and soil are treated, but also human tissue, exploiting the antibacterial and antifungal properties of plasmas, which eliminate pathogens without causing damage to healthy cells.

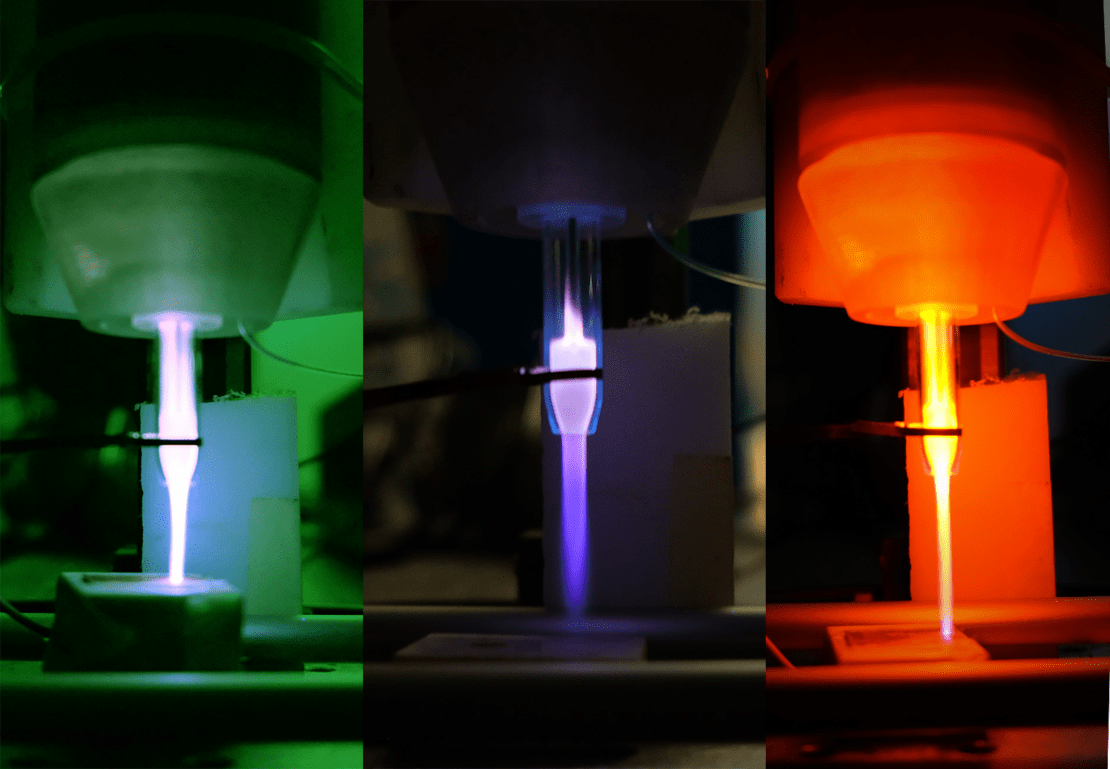

However, each application requires a particular mix of electron temperature, ionized fraction and the type and pressure of the gas used. This has given rise to a broad research field for the study of specific plasma sources for each type of application.

Among these countless lines of research, Consorzio RFX is responsible for studying the specific properties of plasmas and undertaking of the creation of sources for the following sectors: