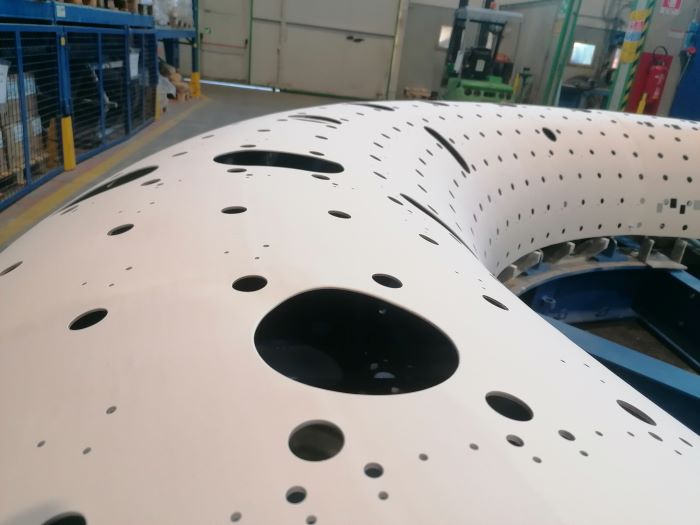

After months of waiting and a long optimization process, the first segment of the shell coated with its white alumina layer has finally arrived at Consorzio RFX!

What is alumina and why is it so important?

Alumina, the ceramic oxide of aluminium, has been chosen to coat the copper shell of RFX-mod2 to electrically insulate it from the plasma. This protective layer is crucial: any damage to the insulation could lead to short circuits among the in-vessel components, causing excessive heating and potentially damaging the shell.

The deposition process

To achieve this, the alumina treatment had to be requalified for a large-scale component, tackling the complexity of its geometry. After rigorous testing on samples to ensure the coating met uniformity and porosity requirements, the deposition process was finalized. It took more than 48 consecutive hours, progressing at 30 microns per hour, until reaching the target thickness of 200 microns.

A team effort

A big thank you to Linde AMT Italy SRL and Brembana&Rolle companies for carrying out the coating process, and to the Consorzio RFX team, with Daniele Aprile and Luigi Cordaro leading the way in this challenge!

Another step forward for RFX-mod2!

What’s next?

In the coming months, we will continue with the coating of the other segments of the shell and the next phases of the reassembly of the RFX-mod2 toroidal complex in view of the start of the next scientific operation campaign. Another step forward in plasma confinement research… and much more to come!