On 8th March 2023, Site Acceptance Tests of MITICA cryo-pumps were successfully completed at the Neutral Beam Test Facility – NBTF in Padua, Italy, under the supervision of ITER IO, Fusion for Energy, and the Consorzio RFX teams.

MITICA is the neutral beam prototype of the main ITER’s heating system that will launch extremely energetic neutral particles into the plasma to make it reach 150 million °C. The facility in Padua has the task to test and improve such a critical system before it is installed in ITER and allow scientists to familiarize with its operation.

The cryopump system is an important component of MITICA as it provides the vacuum conditions necessary during the neutral beam injector operation.

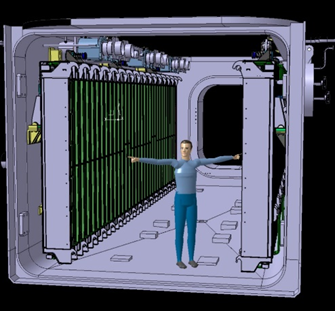

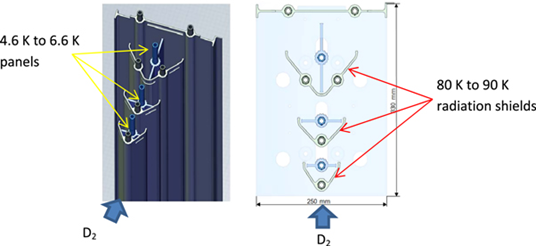

Manufactured by SDMS from Saint-Romans in France, under a contract with F4E, the cryo-pump system is composed of 2 pumping assemblies (8m long, 2.8m high and 0.45 m wide). Each assembly consists of a frame with 32 pumping sections, each one made of 7 hydroformed panels in aluminium alloy and stainless steel, where helium flows at 4K, in the cryo-pumps circuits, and at 80K, in the thermal radiation shield circuits.

“The site acceptance test successfully completed today on MITICA cryo-pumps is an important milestone, which has been possible thanks to an intense and positive collaboration with SDMS, ITER IO and F4E colleagues”, says Stefano Manfrin, RFX Responsible Officer .

Following the successful site acceptance test of MITICA cryo-pumps, the component will be placed in a safe storage to await for its on-site installation.

References:

“Overview of the design of the ITER heating neutral beam injectors”

R S Hemsworth, D Boilson, P Blatchford, M Dalla Palma, G Chitarin, H P L de Esch, F Geli, M Dremel, J Graceffa, D Marcuzzi, G Serianni, D Shah, M Singh, M Urbani and P Zaccaria